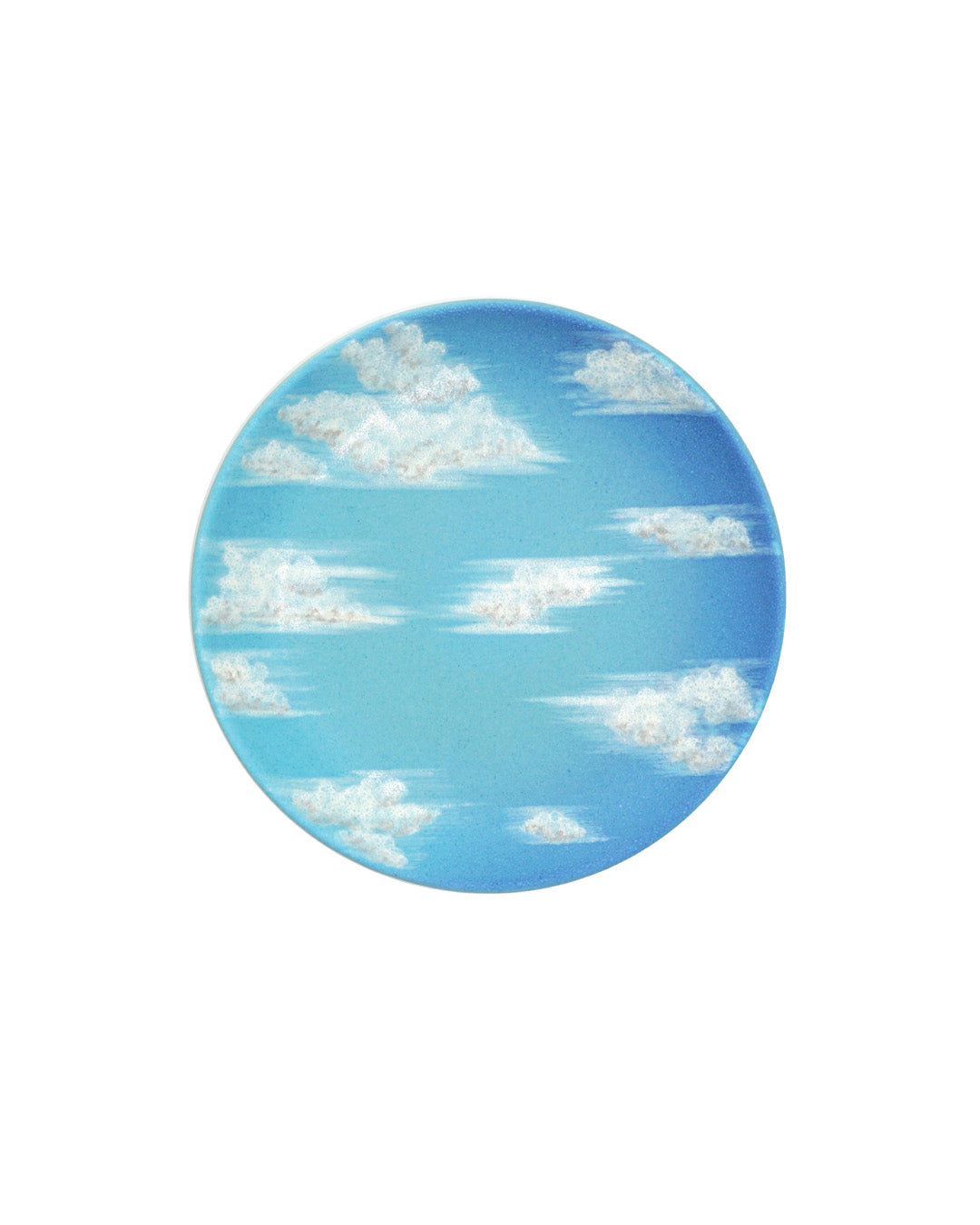

ILARIA BIFFARA E GIAMPAOLO SANTODDÌ

Faenza, ITALY

You might wonder...

en savoir plus sur Pantoú Ceramics

La valeur dans les détails

PLUS QUE DES PRODUITS

Une communauté toujours croissante

Artisans, designers et esprits créatifs sont les protagonistes ! Voulez-vous rejoindre la communauté? Contactez-nous !